Broken parts

To prevent a rod from moving too far sideways. Two switches are located at each rod. These are supposed to be hit whenever a rod moves too far. But these switches are attached with double tape, and have a tendency of falling off. It is a problem mounting them properly, because for them to be effective without being a limitation, they have to be placed with great precision, and holes have to be drilled.

Since the switches fall off, we had an accident with one of the rods moving too far, resulting in a burned out circuit on one of the motor-controller boards. The rod had moved to the end of the possible moving range for the rod, and the engine was still fully powered, resulting in doubling of the current for about 2-3 seconds.

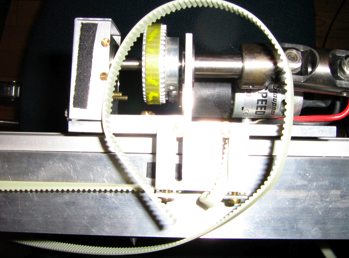

Also in seperate incident, a timing belt snapped (see picture). Unfortunately, they are old and have lost their flexibility.

They aren’t steelwire enforced, so should the problem reoccur, stellwire enforced timing belts would make good substitutes.

Instead of mounting the switches properly, we’ve decided to create a software fix, and remove them entirely, more on this later.